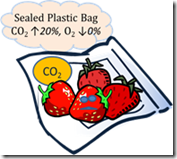

Modified Atmospheric Packaging (MAP) involves passive self-inducement of atmospheric parameters inside any enclosed package. Such specialised packaging exploits advantages of the normal respiratory activity of living fruits and vegetables which cause a change to air composition inside an enclosed pack [much like in a plastic film placed around our head]. The packaging material is designed with semi-permeable material so as to allow a minimal exchange of gases and oxygen with outside air, as a way of keeping the fresh food alive, yet extending its shelf life. MAP does not work to the exclusion of temperature control and both must be used hand-in-hand. Temperature control reduces the respiration rates to a level that can be safely handled by the MAP film or bag.

Modified Atmospheric Packaging (MAP) involves passive self-inducement of atmospheric parameters inside any enclosed package. Such specialised packaging exploits advantages of the normal respiratory activity of living fruits and vegetables which cause a change to air composition inside an enclosed pack [much like in a plastic film placed around our head]. The packaging material is designed with semi-permeable material so as to allow a minimal exchange of gases and oxygen with outside air, as a way of keeping the fresh food alive, yet extending its shelf life. MAP does not work to the exclusion of temperature control and both must be used hand-in-hand. Temperature control reduces the respiration rates to a level that can be safely handled by the MAP film or bag.

The simplest form of this technology is the application of a wax coat (food-grade) to the surface of the fruit. Similarly, selectively permeable plastic is used to package fresh produce.

The simplest form of this technology is the application of a wax coat (food-grade) to the surface of the fruit. Similarly, selectively permeable plastic is used to package fresh produce. In effect, the packaging serves like a molecular sieve and allows for self-induced altering of the atmospheric composition inside the packaging, within specified limits.

A MAP package designed for one product cannot be used with another, unless both commodities have the similar respiratory rates and oxygen needs. High humidity levels, important for fruits and vegs (F&V), are easy to sustain inside MAP.

In MAP, F&V have advantage of a protected and safe environment, all the way from initial packaging to consumer’s hand.

In MAP, F&V have advantage of a protected and safe environment, all the way from initial packaging to consumer’s hand.

In other cases including meat, fish and processed foods, forcible flushing of the package with gas or creating a vacuum is used to counter microbial build up and preserve the product longer. CO2 in carbonated drinks is the most common example. In such cases, the packaging is not permeable.

Ozone Depleting Potential (ODP): Earth's protective ozone layer can get damaged by certain ozone depleting chemical substances. This layer, composed of naturally occurring ozone molecules, extends from about 15 to 30 kilometres in the stratosphere above the Earth's surface and serves to filter 97-99% of the Sun's harmful ultraviolet (UV) radiation. Consequently, any thinning of the ozone layer allows more radiation to reach the Earth's surface - overexposure to UV rays can lead to skin cancer, cataracts, and weakened immune systems. In terms of ecological health, increased UV can lead to reduced crop yield and disruptions in the marine food chain.

Ozone depleting substances (ODS) vary in their capacity to destroy ozone molecules and the Ozone Depleting Potential (ODP) is a ratio of the relative depletion caused by different substances in relation to the value assigned to trichlorofluoromethane (R11 / CFC11) that is assigned the value 1.

CFC11 has 3 chlorine atoms in a molecule – each chlorine atom can destroy over 100,000 ozone molecules.

The Montreal Protocol is the first worldwide agreement designed to protect human health and the environment against the adverse effects of the depletion of the stratospheric ozone shield. The protocol is administered by the United Nations Environment Programme (UNEP), which maintains the list of ozone-depleting substances that are targeted for control, reductions, or total phase-outs. India’s cold-chain primarily uses ammonia, a natural refrigerant with zero ODP. Yet, with the need to develop more pack-houses and reefer transport units, the use of artificial refrigerants will increase and care has to be taken to only use gases that are permitted with acceptable ODP.

From NCCD Glossary – newsletter edn-6 (www.nccd.gov.in) -Pawanexh Kohli

No comments:

Post a Comment

Contribute through suggestions and comments